EMI’s Cutting-Edge Machinery for Miscellaneous Iron Shops

Electro-Mechanical Integrators (EMI) is revolutionizing the way miscellaneous iron shops operate with their cutting-edge machinery and advanced solutions. Since its founding in 1996, EMI has been at the forefront of CNC technology, originally introducing a custom-designed CNC plasma tube cutting machine that simplifies tube processing for weld-ready components.

Today, EMI’s state-of-the-art equipment is empowering fab shops to efficiently produce key miscellaneous metal components, including stairs, handrails, guardrails, and stair stringers.

EMI’s comprehensive range of machines help shops meet the growing demand for precision and speed where there is a skilled labor shortage. Their reliable solutions minimize downtime and streamline operations, making them the go-to partner for many fabrication shops. Trusted by top industry leaders, EMI is shaping the future of the miscellaneous metal industry with innovation, expertise, and a commitment to quality.

For miscellaneous iron shops seeking to enhance production capabilities, EMI tube processing center offers the tools and support needed to stay ahead of the competition.

Key Machines

Key machines like the EMI EL SQRD & EMI TPC 2400 series machines for plasma handrail and miscellaneous processing control as well as the the EMI ACPC for automated angle, channel & flat bar cutting, exemplify EMI's dedication to automate your miscellaneous fab shop.

EMI EL SQRD: Handrail Faster than Ever

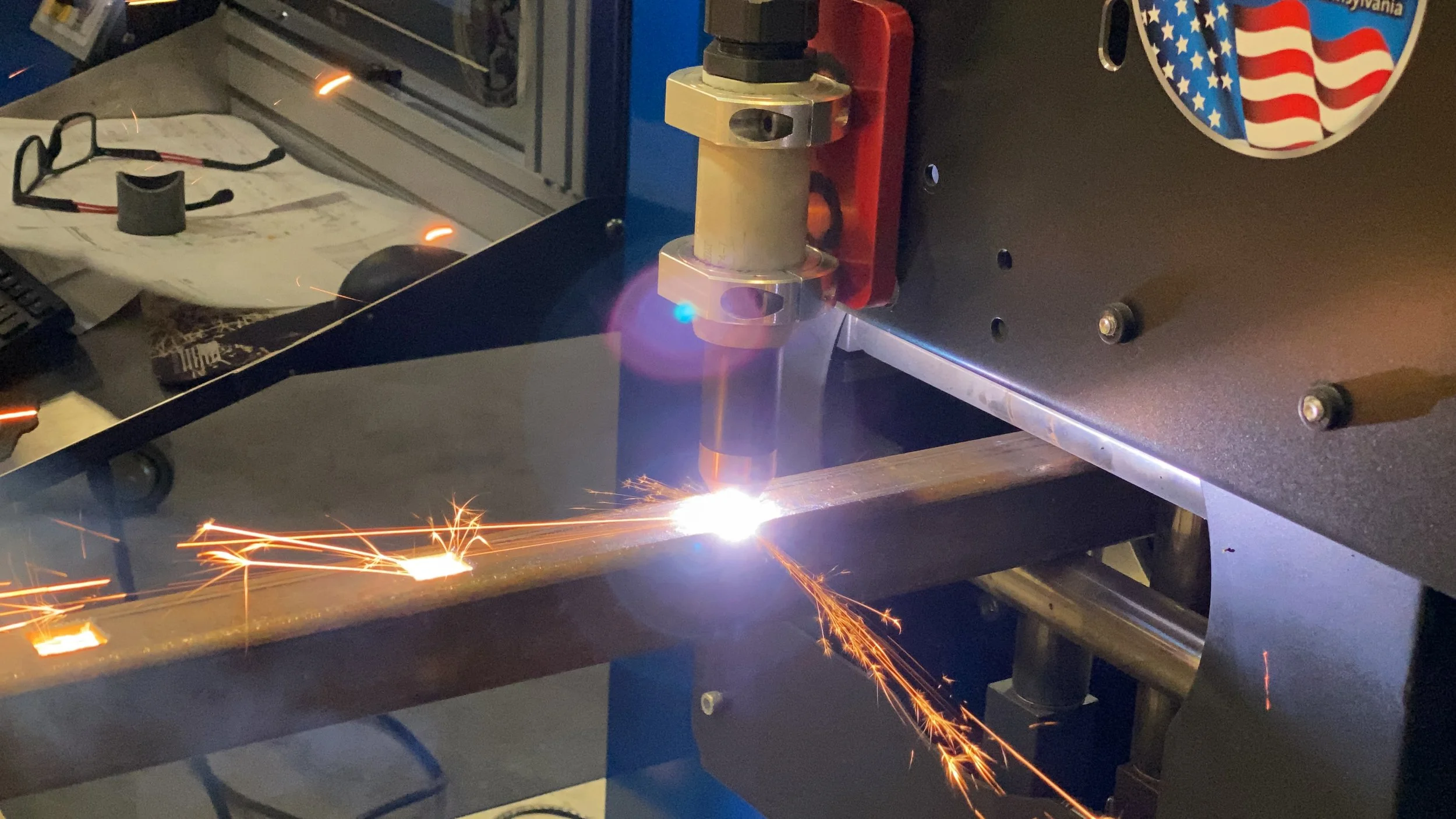

The EMI EL SQRD is designed for high volume plasma cutting of miscellaneous iron for your fab shop to ensure quick turnarounds with simple programming.

Please note that additional tooling may be required.

Material Specifications

Material Shapes:

Round, Square, Rectangular, Angle, C-Channel, Flat Bar

Maximum Work Length:

Loading: 24 ft

Unloading: 8 ft (unsupported in most 2 in and down applications)

Material Diameter

Round: 0.75 in to 6 in (limited to 20 lbs/ft)

Square and Rectangle: 3/4" to 4" Sch80

Angle, C-Channel, Flat Bar: 4"x 4"x 1/2"

Additional Features

CNC Control System:

Centroid CNC Control: User-friendly, US-manufactured system with remote support and diagnostics for nationwide compatibility.

Dual Monitor Station:

Enables simultaneous access to prints, programming, and operations for increased efficiency and reduced clutter.

Cabinet Air Conditioner:

Maintains a cool, dry environment.

Uninterruptible Power Supply (UPS):

Supports the control system during power interruptions for up to 3 minutes.

Air Blast System:

Reduces slag build-up in tubes and enhances smoke evacuation.

Power Filter:

Protects the control system from voltage surges and electrical noise.

This machine allows for rapid, accurate cutting for your misc handrail shop saving time and labor while enhancing production efficiency.

EMI TPC 2464: Advanced Thermal Processing Control

The EMI TPC 2464 is a highly advanced thermal processing control machine, ideal for applications such as heat treatment and welding. It ensures precise temperature regulation, which is crucial for maintaining product quality in sensitive industrial processes.

The TPC2464 is a robust addition to the TPC2400 series, featuring a strengthened X-axis carriage designed for handling heavier materials, including flat bars up to 8 inches. This machine streamlines the processing of various diameters and angles from stock lengths, eliminating the need for manual measuring, sawing, notching, deburring, drilling, and repetitive material handling. By integrating these steps into a single continuous process, the TPC2464 reduces labor and floor space requirements while enhancing profitability.

Please note that additional tooling may be required.

Material Specifications

Material Shapes:

Round, Square, Rectangular, Angle, C-Channel, Flat Bar

Maximum Work Length:

Loading: 24 ft

Unloading: 8 ft (unsupported in most 2 in and down applications)

Material Diameter

Round: 0.75 in to 8 in (limited to 20 lbs/ft)

Square and Rectangle: 3/4" to 6" Sch80

Angle, C-Channel, Flat Bar: 6"x 6"x 1/2"

Additional Features

Plasma Cutting Unit:

Hypertherm Powermax SYNC 105-amp Plasma Unit (includes mounting tray and consumables kit). Hypertherm Details

Automatic Loading:

Designed for round materials with assisted loading for non-round profiles, allowing for multiple stock lengths to be loaded efficiently. Features include an Easy-Off lift system with four pneumatic lifts.

Pneumatic 2-Jaw Chuck/Gripper:

Equipped with six jaws to accommodate materials from 1.0” to 6.7” in diameter, with additional tooling available.

CNC Control System:

Centroid CNC Control: User-friendly, US-manufactured system with remote support and diagnostics for nationwide compatibility.

Dual Monitor Station:

Enables simultaneous access to prints, programming, and operations for increased efficiency and reduced clutter.

Cabinet Air Conditioner:

Maintains a cool, dry environment.

Uninterruptible Power Supply (UPS):

Supports the control system during power interruptions for up to 3 minutes.

Air Blast System:

Reduces slag build-up in tubes and enhances smoke evacuation.

Power Filter:

Protects the control system from voltage surges and electrical noise.

Infeed Damper Kit:

For improved material handling.

Magazine Auto Feed:

Facilitates loading for non-round materials.

The TPC 2464 minimizes material waste while maintaining consistency in high-quality output for larger and heavier handrail / misc parts making it a true workhorse for your shop.

EMI ACPC: Automated Precision Cutting

The EMI ACPC (Angle-Channel Processing Center) is a versatile cutting solution that handles various larger Angle, Channel and Flat Bars. Its precision control systems ensure repeatable, accurate cuts, making it an essential tool for your operations.

The AC-PC processes C-Channel, Angle, and Flat Bar with high accuracy in a single stroke. It features dual monitors and user-friendly, USA-manufactured CNC control.

Please note that additional tooling may be required.

Material Specifications

Material Shapes:

Angle,C-Channel, Flat Bar

Maximum Work Length:

Loading: Up to 40’ with roller tables* additional cost

Unloading: 20’ in most applications with additional tables* additional cost

Material Specifications

Channel: 3"x 12"

Flat Bar:: 3" up to 12"x 3/4"

Angle: 2"x 2" up to 8" x8"x 3/4"

Additional Features

CNC Control:

USA-made Centroid CNC with shared support across other machines.

Remote support and diagnostics.

Powered Material Vise:

Pneumatic operation with manual and software controls.

Dual Monitor Workstation:

Allows simultaneous access to prints, programming, and operations.

Plasma Scribing/Marking:

Hypertherm Powermax 45XP for part numbering and layout lines. Requires compatible modeling software.

Primary Cutting Torch:

Hypertherm Powermax 105 SYNC. Hypertherm Details

Cabinet Air Conditioner:

Maintains a cool, dry environment without requiring compressed air.

Industrial Power Filter:

Protects against high power surges and electrical noise, ensuring stable CNC operation.

Part Programming Software:

PieceMaker™ Software by EMI and Lantek™ Flex3D Plus for advanced marking features. Annual maintenance available for Lantek software.

The ACPC machine is a high volume machine made for larger angle, channel and flat bar that is versatile while delivering consistent production for miscellaneous shops looking to automate their stair stringers and larger angle / flat bar.

EMI’s Impact on Industry

EMI’s advanced machinery line up have revolutionized the way fabrication shops approach handrail and other miscellaneous iron jobs.. The company’s relentless pursuit of innovation and dedication to quality has set new standards in the fields of fabrication, manufacturing, and engineering. By offering solutions like the EL SQRD, EMI TPC 2464, and EMI ACPC, EMI empowers businesses to achieve greater accuracy, efficiency, and operational reliability, ensuring that they remain competitive in a constantly evolving market.

EMI continues to pave the way for the future of the miscellaneous machinery industry. With a proven track record and a commitment to innovation, EMI remains an essential partner for businesses seeking to produce smarter for their miscellaneous shops.